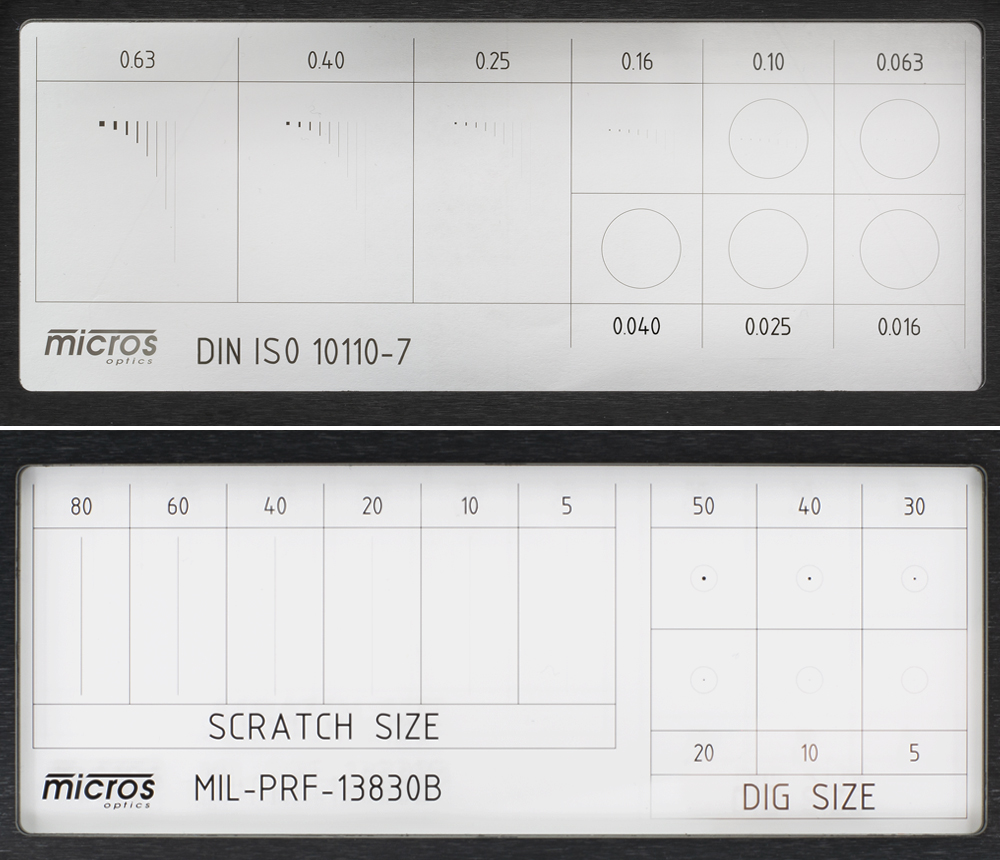

Optical tolerances should be specified for each optical surface individually. On the other hand, specifying design parameters and tolerances that are too tight may result in significant increase in the project cost or even project failure due to inability to manufacture components to specification. Specifying design parameters and tolerances that are too loose may result in inadequate system performance. Design parameters and tolerances should be applicable to the specified material and manufacturing process planned for the system design. Alternately with the use of plastic molding technology the mechanical and optical properties are built into the tooling and with injection molding may be replicated at higher production rates and lower cost for each component.Īppropriate optical design is performed using design and simulation software such as Zemax OpticsStudio, Code V, Oslo or several other optical modeling platforms. While many of these design parameters may be controlled very tightly when designing with glass and metal this comes at great cost as each component is machined individually. For example, mechanical and optical specifications and tolerances may be loosened if the optical design engineer can design the system to allow active alignment of components during assembly. They may vary greatly depending upon the system performance requirements, the assembly method selected, the materials of manufacture and the design experience of the optical engineer performing the design. During the optical design process the base values and tolerances for both mechanical and optical parameters are established. Tolerances normally achievable for glass components may not be appropriate for plastic optics. Optical parameters are much less known to non-optical staff and consist of focal length, surface form (Power/Irregularity), material imperfections, cosmetics (scratch/dig), centering deviation (concentricity, beam deviation, wedge or total indicated runout) and surface roughness. An additional mechanical consideration for plastic optics is center to edge ratio due to the implications this has on final form due to shrink.

Mechanical parameters are fairly straightforward and consist of items such as flange diameter, center thickness (CT), radius of curvature and clear aperture (CA). Manufacturing requirements for optical systems are comprised of mechanical and optical parameters. Plastic Optics Mechanical and Optical Parameters

0 kommentar(er)

0 kommentar(er)